AVK rubber compounds for safe drinking water

Our EPDM rubber recipes are created with focus on minimizing formation of biofilm and ensuring resistance to water treatment chemicals.

No contamination of drinking water

There are many organic substances such as medicinal paraffinic oils and waxes that can migrate from rubber compounds. They act as nutrients for microorganisms, which will then start forming biofilm. AVK EPDM rubber recipes are composed with focus on minimizing the formation of biofilm, so the rubber will not provide a breeding ground for bacteria.

Download DVGW W270 approval regarding microbial growth

How EPDM rubber and ozonation assist in bacterial reduction

AVK's drinking water approved EPDM compounds are resistant to ozone and water treatment chemicals, and are of course taste, smell and color neutral.

Chlorine and other chemicals are commonly used to clean new pipelines or disinfect old ones. Ozone and chlorine may also be added in low concentrations to make the water drinkable.

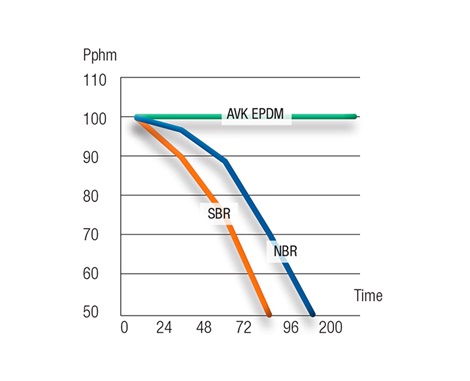

Ozonation is used to reduce smell and taste or to reduce bacterial activity. The chemical reaction will also cause degradation of rubber materials, if not adequately formulated to encounter highly reactive chemicals such as ozone. AVK’s own compound EPDM is superior to any other material, including many other EPDM materials. The unique structure can withstand an extremely high concentration of ozone. After 200 hours of exposure in 200 pphm the properties of AVK’s EPDM have not changed, while both the SBR and NBR grade are suffering.